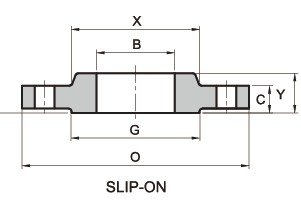

ASME/ANSI B16.5 300 Class Slip On Flange/Standards, Dimensions & Weight

Slip on flanges are designed to be slipped over the pipe and then welded, typically on both the inside and outside, to increase strength and prevent any potential leakage. Compared to other types of flanges, slip on flanges are relatively inexpensive and do not require a high degree of precision when it comes to cutting the pipe to the right length. Some slip on flanges may come with a boss or hub and can be made with a bore that accommodates either a pipe or tube.

- Our company is a manufacturer of ASME/ANSI B16.5 300LB Slip On Flange, which is precisely engineered in accordance with international quality standards. For detailed dimensions of 300 Class Slip On flange, kindly check the table below. Also, you can download the datasheet.

| Product | Slip On Flange |

|---|---|

| Pressure Rating | 300 lb, 300 Class |

| Dimensional Specification | ASME/ANSI B16.5 |

| Size | 1/2″ to 24″ |

| Surface Treatment | Anti-rust Oil, Paint, Zinc, Hot Dipped Galvanized |

| Grades | 304, 304L, 316L, 321, 347, 904L, Duplex, Carbon Steel, Nickel Alloys |

| Test Certificates | As per EN 10204 3.1 |

| Inspection | Videos, Pictures, Inspection Report with Goods |

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub.Y | Bore | Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

Approx. Weight | ||

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 22.4 | 66.5 | 15.7 | 4 | 1/2″ | 0.7 | 1.5 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 27.7 | 82.6 | 19.1 | 4 | 5/8″ | 1.2 | 2.6 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 34.5 | 88.9 | 19.1 | 4 | 5/8″ | 1.4 | 3.1 |

| 1-1/4″ | 32 | 133. 5 | 19.1 | 63.5 | 63.5 | 26.9 | 43.2 | 98.6 | 19.1 | 4 | 5/8″ | 1.8 | 4 |

| 1-1/2″ | 40 | 155. 5 | 20.6 | 69.9 | 73.2 | 30.2 | 49.5 | 114.3 | 22.4 | 4 | 5/8″ | 2.7 | 6 |

| 2″ | 50 | 165. 0 | 22.4 | 84.1 | 91.9 | 33.3 | 62 | 127 | 19.1 | 8 | 5/8″ | 3.2 | 7 |

| 2-1/2″ | 65 | 190. 5 | 25.4 | 100.1 | 104.6 | 38.1 | 74.7 | 149.4 | 22.4 | 8 | 3/4″ | 4.5 | 9.9 |

| 3″ | 80 | 209. 5 | 28.4 | 117.3 | 127 | 42.9 | 90.7 | 168.1 | 22.4 | 8 | 3/4″ | 5.9 | 13 |

| 3-1/2″ | 90 | 228. 5 | 30.2 | 133.4 | 139.7 | 44.5 | 103. 4 | 184.2 | 22.4 | 8 | 3/4″ | 7.5 | 16.5 |

| 4″ | 100 | 254. 0 | 31.8 | 146.1 | 157.2 | 47.8 | 116. 1 | 200.2 | 22.4 | 8 | 3/4″ | 10 | 22 |

| 5″ | 125 | 279. 5 | 35.1 | 177.8 | 185.7 | 50.8 | 143. 8 | 235 | 22.4 | 8 | 3/4″ | 12.5 | 27.5 |

| 6″ | 150 | 317. 5 | 36.6 | 206.2 | 215.9 | 52.3 | 170. 7 | 269.7 | 22.4 | 12 | 3/4″ | 16.5 | 36.4 |

| 8″ | 200 | 381. 0 | 41.1 | 260.4 | 269.7 | 62 | 221. 5 | 330.2 | 25.4 | 12 | 7/8″ | 25.5 | 56 |

| 10″ | 250 | 444. 5 | 47.8 | 320.5 | 323.9 | 66.5 | 276. 4 | 387.4 | 28.4 | 16 | 1″ | 35 | 77 |

| 12″ | 300 | 520. 5 | 50.8 | 374.7 | 381 | 73.2 | 327. 2 | 450.9 | 31.8 | 16 | 1 1/8″ | 52 | 115 |

| 14″ | 350 | 584. 0 | 53.8 | 425.5 | 412.8 | 76.2 | 359. 2 | 514..4 | 31.8 | 20 | 1 1/8″ | 73 | 161 |

| 16″ | 400 | 647. 5 | 57.2 | 482.6 | 469.9 | 82.6 | 410. 5 | 571.5 | 35.1 | 20 | 1 1/4″ | 88 | 194 |

| 18″ | 450 | 711. 0 | 60.5 | 533.4 | 533.4 | 88.9 | 461. 8 | 628.7 | 35.1 | 24 | 1 1/4″ | 115 | 253 |

| 20″ | 500 | 774. 5 | 63.5 | 587.2 | 584.2 | 95.3 | 513. 1 | 685.8 | 35.1 | 24 | 1 1/4″ | 139 | 306 |

| 24″ | 600 | 914. 5 | 69.9 | 701.5 | 692.2 | 106. 4 | 616. 0 | 812.8 | 41.1 | 24 | 1 1/2″ | 212 | 467 |