Steel Pipes & Pipe Fittings Manufacturers, Suppliers & Exporters to Zambia

-

Manufacturers of Steel Pipes & Pipe Fitting in Stainless Steel, Carbon Steel, Alloy Steel, Aluminium & Nickel Alloys

-

100% Quality Guaranteed, with Competitive Prices – PED Certified, ISO Certified, Major TPI and Approvals, OHSAS Certified

-

Steel Pipes, Seamless Pipes, Welded Pipes, ERW Pipes, Galvanized Pipes, Buttweld Fittings, Socket Weld Fittings, Threaded Fittings, Steel Plates, Angles, Channels, Round Bars, Flat Bars, Nuts & Bolts, Fasteners, Valves, Gaskets, Flanged Pipes & Fittings

-

We are professional and international manufacturer, supplier and exporter of stainless steel, aluminium, nickel alloys, carbon steel and alloy steel products in Zambia. With a collective experience of over 30 years, we have emerged as one of the largest just in time exporter of steel and aluminum products in Zambia.

-

Large Exports of Steel Pipe to Zambia – We are a prominent exporter of seamless pipes, welded steel pipes, LSAW pipes, spiral welded pipes and coated steel pipes in Zambia. We produce and supply Steel Pipes, Flanges, Pipe Fittings, Fasteners, Gaskets, Valves, Plates, and other spare parts here for industrial use. Our products are available in over 500 sizes and 10 materials such as alloy steel, super duplex stainless steel, stainless steel, carbon steel and mild steel.

-

Our range of products includes steel plates, rods, bars, angle, channels, steel pipe and tube, forged flange and fittings, elbow, tee, reducer, stub end, gaskets, fasteners, valves etc. We are devoted to provide the best solutions for steel materials and industrial equipment for our respected customers in Lusaka, Kitwe, Chipata, Ndola, Kabwe, Chingola, Livingstone, Luanshya, Mufulira and Kasama, the biggest industrial and commercial cities of Zambia. We have manufacturing set up, sales and export offices in both India and China to meet the immediate and long term steel and aluminium product requirements across the Republic of Zambia.

-

Our focus is to offer quality steel products, with shortest delivery time. We have many customers who order materials for shut down requirements, and we have always met their expected delivery schedule.

Are You Looking for a Steel Pipe & Pipe Fittings Manufacturers?

We are one of the largest steel pipe and pipe fittings manufacturer, supplier and exporter to Zambia. We welcome you to contact us and send us your requirements. Metline specialises in export of carbon steel, stainless steel, and alloy steel pipes and pipe fittings to Zambia. We can offer CIF, Ex-Works, DDP delivery terms. We offer the most competitive prices for steel pipes and pipe fittings for our customers in Zambia.

Why Choose Us?

- One of the largest exporter of steel and aluminium products since the past 30 years.

- We sell from stock, and also directly from mill with shortest possible lead times.

- Quality is a promise, and we strive to meet the most stringent quality requirements of our customers.

- We can offer Exworks, FOB, CFR, CIF delivery prices. We suggest that you let us do the shipping.

- All our products are supplied with Mill Test Certificates, as per EN 10204 3.1

Export Documentation we Provide?

- Commercial Invoice, with all Details including HSN Code

- Packing List including number of boxes, net weight and gross weight, Marks and Numbers

- Material Pictures

- Certificate of Origin Issued by Chamber of Commerce or Embassy

- Letter of Guarantee or Warranty towards Manufacturing Defects & Workmanship

- Material Test Certificates as per EN 10204 3.1

- NABL Approved Laboratory Test Reports

Delivery Time & Price Terms:

- If the items are available in stock, we can delivery on immediate basis, after checking the next stuffing and vessel date.

- For higher quantity and special size orders, we can delivery mostly in 30-45 days time.

- The price terms for delivery to Zambia is use of Beira seaport for shipment by sea. Goods can also be delivered to the nearest international airport.

- Alternatively, we can also offer goods, Ex-works or FOB basis at the port of shipment.

Marking, Packing & Services

- All our products are adequately packed for export shipments.

- All our products will have complete marking details which are co-related to the test certificates.

- We specialize in manufacturing and processing of cut to size steel pipes or special length pipes.

- We also offer cut piece for plates, sheets. We can cut them as per your sizes. We can also cut circles and rings as per your dimensions. The cutting is done through water-jet and laserjet and plasma technologies.

Steel & Aluminium Suppliers in Zambia – Best Quality | Best Prices

One of the Largest Steel Plates, Steel Pipes, Fittings & Flanges Suppliers & Manufacturers in Zambia – We are a professional manufacturer and just in time supplier for steel piping system products, including steel pipes and tubes, forged flanges, flanged pipes and fittings, butt-welding pipe fittings, elbow, tee, reducer, stub end, gaskets, fasteners, and valves in Zambia. In addition to manufacturing steel pipe products, we also operate one of the biggest steel sheets and aluminum plate service center in India and China. Our aluminium, stainless steel, carbon steel and alloy steel products are designed and manufactured in compliance with international standards and are appreciated for their sturdiness, precise dimensions, durability, finish and corrosion resistance. These steel pipes, plates, fittings, fasteners and flanges are available in distinguished sizes, dimensions and thicknesses to cover the requirements of various industries like power plants, automobile, heavy engineering, offshore and chemical. If you are looking to choose the best aluminium, carbon steel, mild steel or stainless steel manufacturer, contact us!

Stainless Steel, Carbon Steel & Alloy Steel Seamless Pipes Manufacturing & Supply Range

| Production Details – Stainless Steel, Carbon Steel & Alloy Steel Seamless Pipes | |

| Outer Diameter | Round Seamless Pipe : 6~710mm |

| Square Seamless Pipes : 10mm x 10mm – 400mm x 400mm | |

| Rectangular Seamless Pipes: 10mm x 20mm -200mm x 400mm | |

| Wall Thickness | Round Welded Pipes: 1.0 – 50.00 mm |

| Square Welded Pipes:1.0mm-20mm | |

| Rectangular Welded Pipes: 0.6mm-20mm | |

| Length | 2m – 5.8m, 6m, 12m |

| Material Grades & Specifications | |

| ASTM A312, A213 | 304, 304L, 304H, 304N, 316, 316L, 316Ti, 317L, 310S, 321, 321H, 347H, S31803, S32750, 347, 330, 825, 904L |

| API5L PSL1 & PSL2 | GR.B, X42, X46, X52, X56, X60 |

| API 5L (44th edition) Appendix H | BNS (L245NS), BQS(L245QS), X42NS(L290NS), X42QS(L290QS), X46QS(L320QS), X52NS(L360NS), X52QS(L360QS), X56QS(L390QS), X60QS(L415QS) |

| API 5CT | J55, K55, N80-1 |

| ASME SA106/ASTM A106 | Grade A, Grade B |

| ASME SA333/ASTM A333 | Grade 6 |

| ASME SA53/ASTM A53 | Grade A, Grade B |

| ASME SA213/ASTM A213 | T2, T5, T9, T11, T12, T22, T91, T92 |

| ASME SA335/ASTM A335 | P1, P2, P5, P9, P11, P12, P21, P22, P91, P92 |

| ASME SA519/ASTM A519 | 1010, 1020, 1026, 4140, 1045, 4130 |

| DIN 2391 | St 35, St45, St52 |

| DIN 17175 | St35.8, St45.8, 15Mo3 |

| EN 10297-1, 2 | E235, E275, E315, E355, E470 |

| EN 10210-1, 2 | S235, S275, S355 |

| EN 10255 | S195T |

| EN 10216-1 | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| EN 10216-2 | 195GH, P235GH, P265GH, 20MnNb6, 16Mo3 |

| EN 10216-3 | P355N, P355NL1, P355NL2 |

| Delivery Condition | Formed, Normalized, Normalized and Tempered, Quenched and Tempered, (Annealed & Pickled for Stainless Steel Pipes) |

| Finish of pipe | Hot Rolled No.1 Mill Finish, Polished, Mirror, Matte, 240 Grit, 400 Grit, 500 Grit for Stainless Steel Pipes |

| Hot dipped galvanized with zinc 200~260g/m2; | |

| Pre-Galvanized with zinc 30~150g/m2 | |

| Painted with Black/Varnish Lacquer | |

| Oil on the Surface to Prevent Rust | |

| Bare Pipe without Painting | |

| Epoxy Painting, FBE Coating, 3PE Coating | |

| Pipe End | Plain End/ Bevel End |

| Groove End | |

| Ends Joint with Flange or Fittings | |

| Threaded on Two Ends, One End with Coupling, One End with Plastic Cap | |

| Marking | As Per Client Requirements or Mill Standard |

| Painting Method: Spray White/Black Paint | |

| Packing | OD Not Less Than 273mm: Loose Packing – Piece by Piece |

| OD less than 273mm – In Hexagonal Seaworthy Bundles Packed by Steel Strips | |

| On Request Small Sizes May be Nested into Big Sizes | |

| Production Method | Seamless, Hot Rolled, Cold Drawn, Heat Treated, Impact Tested |

| Trade Term | FOB, CFR, CIF, EXW |

| Payment Term | T/T, LC |

| Delivery Time | 15-45 days (based on quantity) after receiving advanced payment by T/T or LC |

Steel Pipes, Tubes and Tubing’s

Quality : ISO, PED, NABL, TPI Inspection

Product Types: Seamless, ERW, LSAW, EFW

Specifications: ANSI B36.10, ANSI B36.19

- Carbon Steel Pipes: ASTM A53 Gr. B, ASTM A106 Gr. B, ASTM A333, Gr.3, Gr.6, API 5LA, B, X42, X46, X52, X56, X60, X65, X70

- Stainless Steel Pipes: ASTM A312, TP304/304L, TP316/316L, TP310S/310H, TP321/321H, TP347/347H, TP904L

- Alloy Steel/Chrome Moly Pipes: ASTM A355 P1, P5, P9, P11, P12, P22, P91

- Duplex Stainless Steel: ASTM A790 UNS S31803, UNS S32750, UNS S32760

- Special Alloy Pipes: Inconel 600, Inconel 625, Inconel 718, Inconel X-750, Incoloy 800, Incoloy 800H, Incoloy 825, Hastelloy C276, Monel 400, Monel K-500

Sizes

- Carbon Steel Pipes : Seamless: 1/2’’~24’’NB, ERW: 1/2’’~40’’NB, LSAW: 18’’~72’’NB

- Stainless Steel Pipes: Seamless: 1/2’’~24’’NB, ERW: 1/2’’~40’’NB, EFW: 18’’~80’’NB

Buttweld Pipe Fittings

Quality : ISO, PED Certified, TPI Inspection

Production Standard: ASME B16.9, ASME B16.28, ASMEB36.10M, JIS B23.11, JIS G3452, JIS G3457, DIN 2448, DIN 2458, DIN 2605, DIN 2615, DIN 2616, DIN 2617

Production size: 1/2 inch – 48 inch ( 15mm – 1200mm )

Materials

- Carbon Steel Fittings: ASTM A234 WPB, WPC; ASTM A420 WPL9, WPL3, WPL6, WPHY-42, WPHY-46, WPHY-52, WPHY-56, WPHY-60, WHPY-65, WHPY-70

- Stainless Steel Fittings: ASTM A403 WP304/304L, WP316/316L, WP321, WP347, WPS31254

- Alloy Steel Fittings: ASTM A234 WP1, WP12, WP11, WP22, WP5, WP9, WP91

- Duplex & Super Duplex Stainless Steel Fittings: ASTM A815 UNS S31803, UNS S32750, UNS S32760

- Special Alloy Fittings: Inconel 600, Inconel 625, Inconel 718, Inconel X-750, Incoloy800, Incoloy 800H, Incoloy 825, Hastelloy C276, Monel 400, Monel K-500

Forged Socket Weld and Threaded Pipe Fittings

Quality Control: ISO , NABL Testing, PED Certified, TPI Inspection

Production Standard: ASME B16.11 ,JIS B2316, DIN Standards

Production size: 1/2 inch – 4 inch ( 15mm – 100mm )

Materials

- Carbon Steel Pipe Fittings: ASTM A105, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F52, F56, F60, F65, F70

- Stainless Steel Pipe Fittings: ASTM A182 F304/304L, F316/316L, F316H, F310, F321, F44(UNS S31254)

- Alloy Steel Pipe Fittings: ASTMA 182F1, F5a, F9, F11, F12, F22, F91

- Duplex & Super Duplex Stainless Steel Pipe Fittings: ASTM A182 F51/UNS S31803, F53/UNS S32750, F55/UNS S32760

- Special Alloy Pipe Fittings: Inconel 600, Inconel 625, Inconel 718, Inconel X-750, Incoloy 800, Incoloy 800H, Incoloy 825, Hastelloy C276, Monel 400, Monel K-500

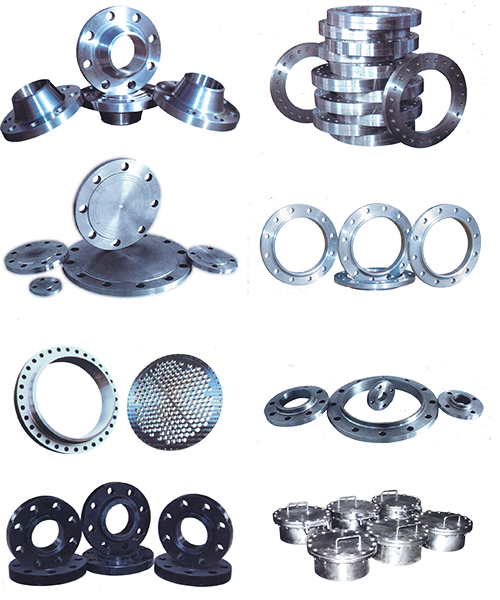

Steel Pipe Flanges

Quality : ISO, PED Certified, NABL Testing, TPI Inspection

Production Standard: ANSI B16.5, ANSI B16.47… API, MSS-SP44, DIN, JIS, BS, AWWA C207, Light weight 125 lbs, Orifice, Taylor type, Hub Blind, RTJ, spectacle blind, ring spade, blind spade, BS, Long welding neck.

Production Sizes: 1/2 inch – 120 inch ( 15mm – 3000mm )

Materials

- Carbon Steel Flanges: ASTM A 105, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A 694 F42, F46, F52, F56, F60, F65, F70

- Stainless Steel Flanges: ASTM A 182 F304/304L, F316/316L, F316H, F310, F321, F44 (UNS S31254)

- Alloy Steel Flanges: ASTM A182 F1, F5a, F9, F11, F12, F22, F91

- Duplex & Super Duplex Stainless Steel Flanges: ASTM A 182 F51/ UNS S31803, F53/UNS S32750, F55/UNS S32760

- Special Alloy Flanges: Inconel 600, Inconel 625, Inconel 718, Inconel X-750, Incoloy 800, Incoloy 800H, Incoloy 825, Hastelloy C276, Monel 400, Monel K-500