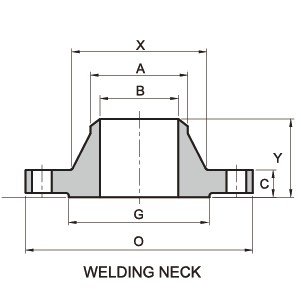

ASME/ANSI B16.5 600 Class Weld Neck Flange/Standards, Dimensions & Weight

Weld Neck Flange is flanges that designed to be joined to a piping system by butt welding. This kind of flange include lots of specification, weld neck flange is expensive because of its long neck and cost of people for contact WN flange with pipeline or fitting, but is preferred for high stress applications. The necks, or hubs, transmits stresses to the pipeline. The gradual transition of thickness from the base of the hub to the wall thickness at the butt weld provides important reinforcement of the Weld Neck flange. The bore of Weld-Neck flange matches bore of the pipeline, reducing turbulence and erosion.

- Our company is a manufacturer of ASME/ANSI B16.5 600LB WN Flange, which is precisely engineered in accordance with international quality standards. For detailed dimensions of 150 Class Weld Neck flange, kindly check the table below. Also, you can download the datasheet

| Product | Weld Neck Flange |

|---|---|

| Pressure Rating | 600 lb, 600 Class |

| Dimensional Specification | ASME/ANSI B16.5 |

| Size | 1/2″ to 24″ |

| Surface Treatment | Anti-rust Oil, Paint, Zinc, Hot Dipped Galvanized |

| Grades | 304, 304L, 316L, 321, 347, 904L, Duplex, Carbon Steel, Nickel Alloys |

| Test Certificates | As per EN 10204 3.1 |

| Inspection | Videos, Pictures, Inspection Report with Goods |

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Hub Diam. Chamfer of W.N |

Length Hub | Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

Approx. Weight | ||

| inch | dn | O | C | X | G | A | Y | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 52.3 | 66.5 | 15.7 | 4 | 1/2″ | 0.9 | 2 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 57.2 | 82.6 | 19.1 | 4 | 5/8″ | 1.6 | 3.5 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 62 | 88.9 | 19.1 | 4 | 5/8″ | 1.9 | 4.2 |

| 1-1/4″ | 32 | 133. 5 | 20.6 | 63.5 | 63.5 | 28.4 | 66.5 | 98.6 | 19.1 | 4 | 5/8″ | 2.6 | 5.8 |

| 1-1/2″ | 40 | 155. 5 | 22.4 | 69.9 | 73.2 | 31.8 | 69.9 | 114.3 | 22.4 | 4 | 3/4″ | 3.6 | 8 |

| 2″ | 50 | 165. 0 | 25.4 | 84.1 | 91.9 | 36.6 | 73.2 | 127 | 19.1 | 8 | 5/8″ | 4.7 | 10.4 |

| 2-1/2″ | 65 | 190. 5 | 28.4 | 100.1 | 104.6 | 41.1 | 79.2 | 149.4 | 22.4 | 8 | 3/4″ | 4.8 | 15 |

| 3″ | 80 | 209. 5 | 31.8 | 117.3 | 127 | 46 | 82.6 | 168.1 | 22.4 | 8 | 3/4″ | 8.7 | 19.3 |

| 3-1/2″ | 90 | 228. 5 | 35.1 | 133.4 | 139.7 | 49.3 | 85.9 | 184.2 | 25.4 | 8 | 7/8″ | 11.6 | 25.5 |

| 4″ | 100 | 273. 0 | 38.1 | 152.4 | 157.2 | 53.8 | 101. 6 | 215.9 | 25.4 | 8 | 7/8″ | 18.4 | 40.5 |

| 5″ | 125 | 330. 0 | 44.5 | 189 | 185.7 | 60.5 | 114. 3 | 266.7 | 28.4 | 8 | 1″ | 31 | 68 |

| 6″ | 150 | 355. 5 | 47.8 | 222.3 | 215.9 | 66.5 | 117. 3 | 292.1 | 28.4 | 12 | 1″ | 37 | 81.4 |

| 8″ | 200 | 419. 0 | 55.6 | 273.1 | 269.7 | 76.2 | 133. 4 | 349.3 | 31.8 | 12 | 1 1/8″ | 54.5 | 120 |

| 10″ | 250 | 508. 0 | 63.5 | 342.9 | 323.9 | 85.9 | 152. 4 | 431.8 | 35.1 | 16 | 1 1/4″ | 98.5 | 195 |

| 12″ | 300 | 559. 0 | 66.5 | 400.1 | 381 | 91.9 | 155. 4 | 489 | 35.1 | 20 | 1 1/4″ | 105 | 231 |

| 14″ | 350 | 603. 5 | 69.9 | 431.8 | 412.8 | 93.7 | 165. 1 | 527.1 | 38.1 | 20 | 1 3/8″ | 150 | 330 |

| 16″ | 400 | 686. 0 | 76.2 | 495.3 | 469.9 | 106.4 | 177. 8 | 603.3 | 41.1 | 20 | 1 1/2″ | 177 | 390 |

| 18″ | 450 | 743. 0 | 82.6 | 546.1 | 533.4 | 117.3 | 184. 2 | 654.1 | 44.5 | 20 | 1 5/8″ | 228 | 503 |

| 20″ | 500 | 813. 0 | 88.9 | 609.6 | 584.2 | 127 | 190. 5 | 723.9 | 44.5 | 24 | 1 5/8″ | 285 | 628 |

| 24″ | 600 | 940. 0 | 101.6 | 717.6 | 692.2 | 139.7 | 203. 2 | 838.2 | 50.8 | 24 | 1 7/8″ | 372 | 820 |

Note:

1) 7 mm raised face regularly furnished above Class 400 unless otherwise ordered.