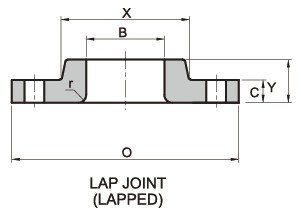

ASME/ANSI B16.5 900 Class Lap Joint Flange/Standards, Dimensions & Weight

Lap Joint Flanges, also known as Loose flanges, are utilized in piping systems where lapped pipes or lap joint stub ends are fitted. These items come with a higher initial cost when compared to welding neck flanges, but their combined cost is only approximately one-third higher. Their pressure-holding ability is similar to slip-on flanges and their fatigue life is much less than that of welding neck flanges.heir ability to swivel flanges and align bolt holes considerably simplifies the erection of large diameter or rigid piping. Lap Joint flanges have some unique benefits. The ability to swivel around the pipe enables the opposing flange bolt holes to be lined up easily. Furthermore, the lack of contact with fluid in the pipe often permits the use of inexpensive carbon steel flanges with corrosion-resistant pipes. In systems that corrode or erode quickly, these flanges can be salvaged for reuse.

| Product | Lap Joint Flange |

|---|---|

| Pressure Rating | 900 lb, 900 Class |

| Dimensional Specification | ASME/ANSI B16.5 |

| Size | 1/2″ to 24″ |

| Surface Treatment | Anti-rust Oil, Paint, Zinc, Hot Dipped Galvanized |

| Grades | 304, 304L, 316L, 321, 347, 904L, Duplex, Carbon Steel, Nickel Alloys |

| Test Certificates | As per EN 10204 3.1 |

| Inspection | Videos, Pictures, Inspection Report with Goods |

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Length Hub | Bore | Corner Radius of Bore |

Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

Approx. Weight | ||

| inch | dn | O | C | X | Y | B | R | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 120.7 | 22.4 | 38.1 | 31.8 | 22.9 | 3 | 82.6 | 22.4 | 4 | 3/4″ | 1.8 | 4 |

| 3/4″ | 20 | 130 | 25.4 | 44.5 | 35.1 | 28.2 | 3 | 88.9 | 22.4 | 4 | 3/4″ | 2.3 | 5 |

| 1″ | 25 | 149.4 | 28.4 | 52.3 | 41.1 | 35.1 | 3 | 101.6 | 25.4 | 4 | 7/8″ | 3.6 | 7.9 |

| 1-1/4″ | 32 | 158.8 | 28.4 | 63.5 | 41.1 | 43.7 | 4.8 | 111.3 | 25.4 | 4 | 7/8″ | 4.1 | 9 |

| 1-1/2″ | 40 | 177.8 | 31.8 | 69.9 | 44.5 | 50 | 6.4 | 124 | 28.4 | 4 | 1″ | 5.4 | 12 |

| 2″ | 50 | 215.9 | 38.1 | 104.6 | 57.2 | 62.5 | 7.9 | 165.1 | 25.4 | 8 | 7/8″ | 10.5 | 23.1 |

| 2-1/2″ | 65 | 244.3 | 41.1 | 124 | 63.5 | 75.4 | 7.9 | 190.5 | 28.4 | 8 | 1″ | 15.8 | 34.8 |

| 3″ | 80 | 241.3 | 38.1 | 127 | 53.8 | 91.4 | 9.7 | 190.5 | 25.4 | 8 | 7/8″ | 11.8 | 26 |

| 4″ | 100 | 292.1 | 44.5 | 158.8 | 69.9 | 116.8 | 11.2 | 235 | 31.8 | 8 | 1 1/8″ | 22.6 | 49.8 |

| 5″ | 125 | 349.3 | 50.8 | 190.5 | 79.2 | 144.5 | 11.2 | 279.4 | 35.1 | 8 | 1 1/4″ | 36.5 | 80.5 |

| 6″ | 150 | 381 | 55.6 | 235 | 85.9 | 171.5 | 12.7 | 317.5 | 31.8 | 12 | 1 1/8″ | 47.5 | 105 |

| 8″ | 200 | 469.9 | 63.5 | 298.5 | 114.3 | 222.3 | 12.7 | 393.7 | 38.1 | 12 | 1 3/8″ | 86 | 190 |

| 10″ | 250 | 546.1 | 69.9 | 368.3 | 127 | 277.4 | 12.7 | 469.9 | 38.1 | 16 | 1 3/8″ | 124 | 273 |

| 12″ | 300 | 609.6 | 79.2 | 419.1 | 142.7 | 328.2 | 12.7 | 533.4 | 38.1 | 20 | 1 3/8″ | 167 | 368 |

| 14″ | 350 | 641.4 | 85.9 | 450.9 | 155.4 | 360.2 | 12.7 | 558.8 | 41.1 | 20 | 1 1/2″ | 180 | 397 |

| 16″ | 400 | 704.9 | 88.9 | 508 | 165.1 | 411.2 | 12.7 | 616 | 44.5 | 20 | 1 5/8″ | 210 | 463 |

| 18″ | 450 | 787.4 | 101.6 | 565.2 | 190.5 | 462.3 | 12.7 | 685.8 | 50.8 | 20 | 1 7/8″ | 294 | 648 |

| 20″ | 500 | 857.3 | 108 | 622.3 | 209.6 | 514.4 | 12.7 | 749.3 | 53.8 | 20 | 2″ | 365 | 805 |

| 24″ | 600 | 1041 | 139.7 | 749.3 | 266.7 | 616 | 12.7 | 901.7 | 66.5 | 20 | 2 1/2″ | 700 | 1543 |