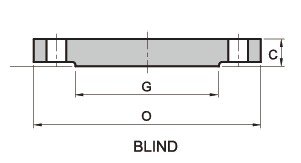

ASME/ANSI B16.5 600 Class Blind Flange/Standards, Dimensions & Weight

Blind flanges come in many different varieties and are designed to seal off piping systems without an opening. They provide convenient access to a closed line when needed. Blind flanges for low pressure pipe systems are often attached using threading or screwing. Taurus, a manufacturer of blind flanges, offers a range of industrial blind flanges in ANSI B16.5 and other specifications.

- Our company is a manufacturer of ASME/ANSI B16.5 600 Blind Flange, which is precisely engineered in accordance with international quality standards. For detailed dimensions of 600 Class blind flange, kindly check the table below. Also, you can download the datasheet

| Product | Blind Flange |

|---|---|

| Pressure Rating | 600 lb, 600 Class |

| Dimensional Specification | ASME/ANSI B16.5 |

| Size | 1/2″ to 24″ |

| Surface Treatment | Anti-rust Oil, Paint, Zinc, Hot Dipped Galvanized |

| Grades | 304, 304L, 316L, 321, 347, 904L, Duplex, Carbon Steel, Nickel Alloys |

| Test Certificates | As per EN 10204 3.1 |

| Inspection | Videos, Pictures, Inspection Report with Goods |

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diameter of Raised Face | Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

Approx. Weight | ||

| inch | dn | O | C | G | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 35.1 | 66.5 | 15.7 | 4 | 1/2″ | 0.8 | 1.8 |

| 3/4″ | 20 | 117. 5 | 15.7 | 42.9 | 82.6 | 19.1 | 4 | 5/8″ | 1.4 | 3.1 |

| 1″ | 25 | 124. 0 | 17.5 | 50.8 | 88.9 | 19.1 | 4 | 5/8″ | 1.7 | 3.7 |

| 1-1/4″ | 32 | 133. 5 | 20.6 | 63.5 | 98.6 | 19.1 | 4 | 5/8″ | 2.4 | 5.3 |

| 1-1/2″ | 40 | 155. 5 | 22.4 | 73.2 | 114.3 | 22.4 | 4 | 3/4″ | 3.4 | 7.5 |

| 2″ | 50 | 165. 0 | 25.4 | 91.9 | 127 | 19.1 | 8 | 5/8″ | 4.4 | 9.7 |

| 2-1/2″ | 65 | 190. 5 | 28.4 | 104.6 | 149.4 | 22.4 | 8 | 3/4″ | 6.8 | 15 |

| 3″ | 80 | 209. 5 | 31.8 | 127 | 168.1 | 22.4 | 8 | 3/4″ | 8.9 | 19.7 |

| 3-1/2″ | 90 | 228. 5 | 35.1 | 139.7 | 184.2 | 25.4 | 8 | 7/8″ | 12.7 | 28 |

| 4″ | 100 | 273. 0 | 38.1 | 157.2 | 215.9 | 25.4 | 8 | 7/8″ | 18.6 | 41 |

| 5″ | 125 | 330. 0 | 44.5 | 185.7 | 266.7 | 28.4 | 8 | 1″ | 30.8 | 68 |

| 6″ | 150 | 355. 5 | 47.8 | 215.9 | 292.1 | 28.4 | 12 | 1″ | 38 | 83.6 |

| 8″ | 200 | 419. 0 | 55.6 | 269.7 | 349.3 | 31.8 | 12 | 1 1/8″ | 62.2 | 137 |

| 10″ | 250 | 508. 0 | 63.5 | 323.9 | 431.8 | 35.1 | 16 | 1 1/4″ | 102 | 225 |

| 12″ | 300 | 559. 0 | 66.5 | 381 | 489 | 35.1 | 20 | 1 1/4″ | 132 | 291 |

| 14″ | 350 | 603. 5 | 69.9 | 412.8 | 527.1 | 38.1 | 20 | 1 3/8″ | 158 | 348 |

| 16″ | 400 | 686. 0 | 76.2 | 469.9 | 603.3 | 41.1 | 20 | 1 1/2″ | 225 | 496 |

| 18″ | 450 | 743. 0 | 82.6 | 533.4 | 654.1 | 44.5 | 20 | 1 5/8″ | 285 | 628 |

| 20″ | 500 | 813. 0 | 88.9 | 584.2 | 723.9 | 44.5 | 24 | 1 5/8″ | 365 | 805 |

| 24″ | 600 | 940. 0 | 101.6 | 692.2 | 838.2 | 50.8 | 24 | 1 7/8″ | 532 | 1170 |

Note:

1) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.