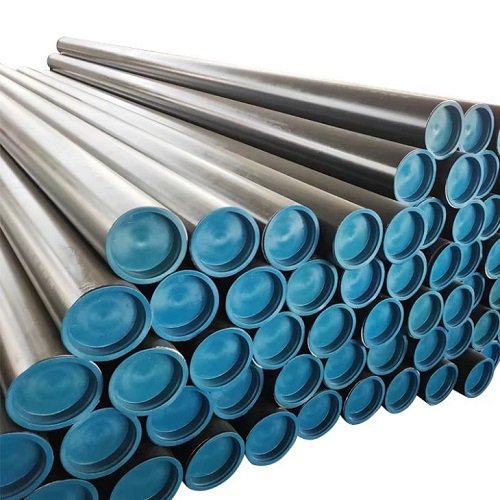

| Production Details – Stainless Steel, Carbon Steel & Alloy Steel Seamless Pipes |

| Outer Diameter |

Round Seamless Pipe : 6~710mm |

| Square Seamless Pipes : 10mm x 10mm – 400mm x 400mm |

| Rectangular Seamless Pipes: 10mm x 20mm -200mm x 400mm |

| Wall Thickness |

Round Welded Pipes: 1.0 – 50.00 mm |

| Square Welded Pipes:1.0mm-20mm |

| Rectangular Welded Pipes: 0.6mm-20mm |

| Length |

2m – 5.8m, 6m, 12m |

| Material Grades & Specifications |

| ASTM A312, A213, A790, A815 |

304, 304L, 304H, 304N, 316, 316L, 316Ti, 317L, 310S, 321, 321H, 347H, S31803, S32750, 347, 330, 825, 904L |

| API5L PSL1 & PSL2 |

GR.B, X42, X46, X52, X56, X60 |

| API 5L (44th edition) Appendix H |

BNS (L245NS), BQS(L245QS), X42NS(L290NS), X42QS(L290QS), X46QS(L320QS), X52NS(L360NS), X52QS(L360QS), X56QS(L390QS), X60QS(L415QS) |

| API 5CT |

J55, K55, N80-1 |

| ASME SA106/ASTM A106 |

Grade A, Grade B |

| ASME SA333/ASTM A333 |

Grade 6 |

| ASME SA53/ASTM A53 |

Grade A, Grade B |

| ASME SA213/ASTM A213 |

T2, T5, T9, T11, T12, T22, T91, T92 |

| ASME SA335/ASTM A335 |

P1, P2, P5, P9, P11, P12, P21, P22, P91, P92 |

| ASME SA519/ASTM A519 |

1010, 1020, 1026, 4140, 1045, 4130 |

| DIN 2391 |

St 35, St45, St52 |

| DIN 17175 |

St35.8, St45.8, 15Mo3 |

| EN 10297-1, 2 |

E235, E275, E315, E355, E470 |

| EN 10210-1, 2 |

S235, S275, S355 |

| EN 10255 |

S195T |

| EN 10216-1 |

P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| EN 10216-2 |

195GH, P235GH, P265GH, 20MnNb6, 16Mo3 |

| EN 10216-3 |

P355N, P355NL1, P355NL2 |

| Delivery Condition |

Formed, Normalized, Normalized and Tempered, Quenched and Tempered, (Annealed & Pickled for Stainless Steel Pipes) |

| Finish of pipe |

Hot Rolled No.1 Mill Finish, Polished, Mirror, Matte, 240 Grit, 400 Grit, 500 Grit for Stainless Steel Pipes |

| Hot dipped galvanized with zinc 200~260g/m2; |

| Pre-Galvanized with zinc 30~150g/m2 |

| Painted with Black/Varnish Lacquer |

| Oil on the Surface to Prevent Rust |

| Bare Pipe without Painting |

| Epoxy Painting, FBE Coating, 3PE Coating |

| Pipe End |

Plain End/ Bevel End |

| Groove End |

| Ends Joint with Flange or Fittings |

| Threaded on Two Ends, One End with Coupling, One End with Plastic Cap |

| Marking |

As Per Client Requirements or Mill Standard |

| Painting Method: Spray White/Black Paint |

| Packing |

OD Not Less Than 273mm: Loose Packing – Piece by Piece |

| OD less than 273mm – In Hexagonal Seaworthy Bundles Packed by Steel Strips |

| On Request Small Sizes May be Nested into Big Sizes |

| Production Method |

Seamless, Hot Rolled, Cold Drawn, Heat Treated, Impact Tested |

| Trade Term |

FOB, CFR, CIF, EXW |

| Payment Term |

T/T, LC |

| Delivery Time |

15-45 days (based on quantity) after receiving advanced payment by T/T or LC |

Reviews

There are no reviews yet.