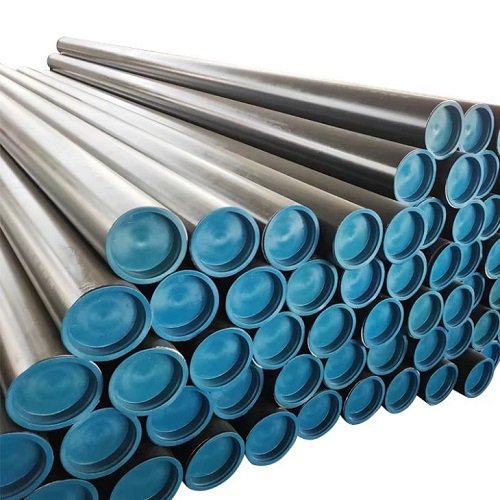

Metline is a specialized manufacturer and factory supplier of Longitudinal Submerged-Arc Welded (LSAW) carbon steel pipes for the Oil and Gas, Petrochemical, Agricultural and Construction Industries. We can supply high quality LSAW pipes with various standards, including but not limited to API 5L GR A, GR B, X42, X46, X56, X60, X65, X70. If you have any special request we can offer you the customized services. Besides LSAW pipes we can also supply carbon steel ERW pipes, spiral welded pipes, seamless steel pipes & fittings and stainless steel tubes.

Generally, welded steel pipes can be divided into ERW pipes, SSAW pipes and LSAW pipes according to the welding technologies involved to manufacture the product. Submerged arc welded pipes are manufactured by bending and welding ordinary steel plates. The SAW type is commonly used for oil and gas transmission lines (API 5L). The most common variations of submerged arc welding pipes are: LSAW (longitudinal welding), DSAW (double submerged arc welding, the weld is applied on both the inner and outer surface) and SSAW or HSAW (spiral welded pipe, generally used for water transmission and distribution but not for oil & gas applications).

LSAW Pipes from UOE Mill – UOE mill adopts U & O forming, the formed pipes are bonded inside through 5 internal welding stations with three wires, and welded outside through 4 external welding stations with three wires. In accordance with various requirements of the customers, the bonded pipe can be broadened either by mechanical or hydrostatic expander to improve dimensional accuracy, and remove recurring tension.

JCOE SAWL PIPES (PRESS BENDING) – This is large diameter longitudinal submerged arc welded (SAWL) pipe production line in China. The mill adopts progressive flexing process, featuring evenly distributed forming stress, high uniformity of dimension, boundless sizes variation & broad product range, and high flexibility, etc.

JCOE SAWL PIPES (ROLL BENDING) – This is the first big diameter longitudinal submerged arc bonded (SAWL) pipe production line in China. The mill embraces constant axis twisting J-C-O forming procedure with characteristics of high forming precision and performance along with well balanced distribution of forming stress. The mill has the advantages of large specs and can produce pipes in any size within its production range.

Production, Supply & Manufacturing Range for Straight Seam Welded Steel Pipe (LSAW Steel Pipes)

| Process: |

Longitudinal Submerged Arc Welded Pipe, Straight Seam Welded Pipes |

| Usage: |

Used for Low Pressure Liquid Transportation, such as Water, Gas, and Oil, Construction, Piping and Pilling Works |

| Standard: |

API 5L, ASTM A252, EN10217-1,2,5, EN10219-1, BS, JIS, IS |

| Certificate: |

EN10217, EN10219, API 5L PSL1/ PSL2, API 5CT |

| Out Diameter: |

219.1 mm – 3048mm (8″-120″) |

| Wall Thickness: |

4mm – 30mm |

| Length: |

3 – 70 M |

| Steel Grade: |

API 5L: GR A, GR B, X42, X46, X56, X60, X65, X70 |

| ASTM A252 GR 1, GR 2, GR 3 |

| BS 4360: Grade 43, Grade 50 |

| EN: S275JR, S275J0H, S275J2H, S355JRH, S355J0H, S355J2H |

| Surface: |

Fusion Bond Epoxy Coating, Coal Tar Epoxy, FBE, 3LPE, 3LPP, 2LPE, Vanish Coating, Bitumen Coating, Black Oil Coating as per customer’s requirement |

| Test: |

Chemical Component Analysis, Mechanical Properties (Ultimate Tensile Strength, Yield Strength, Elongation), Technical Properties (Bending Test, Charp-v Impact Test) Hydrostatic Test, X-Ray Test, Ultrasonic Test |

| Mill Test Certificate: |

EN 10204/3.1B |

Reviews

There are no reviews yet.