SA335 P91 Alloy Steel Pipe Manufacturers & Suppliers in Tunisia

-

UNS K91560 Grade P91 Pipes – Manufacturer & Exporter of A335 Gr. P91 Alloy Steel Pipes or Chrome Moly Pipes to Tunisia in Size Range of 1″ to 48″. We Export P91 Alloy Steel Pipes to Our Customers in Tunis, Sfax, Sousse, Ettadhamen, Kairouan, Gabès, Bizerte, Aryanah, Gafsa, El Mourouj among others.

-

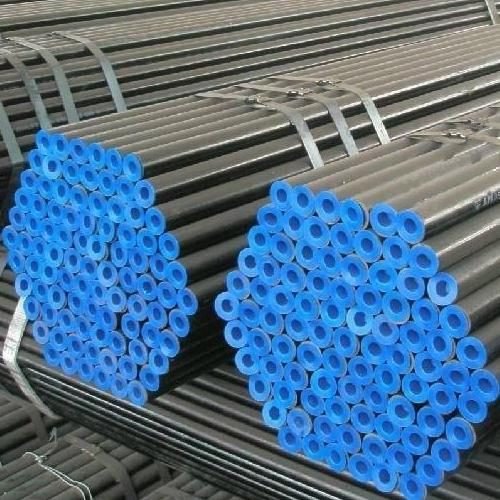

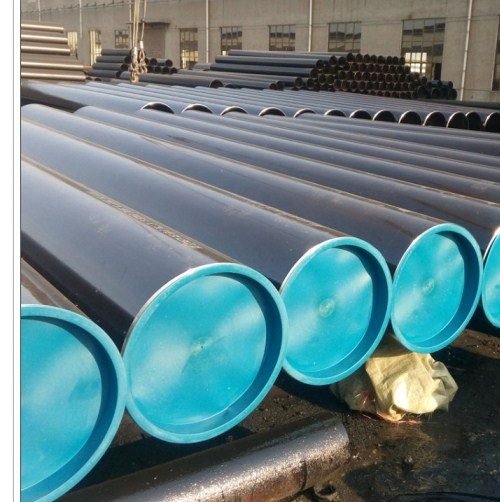

A335 Gr. P91 Alloy Steel Pipes in Size 1″ to 48″ in thickness Upto 40mm.

-

A234 WP91 Buttweld Fittings, Elbow, Tee, Reducer, U Bends are Available in Size Range of 1″ to 48″.

-

A182 F91 Forged Flanges are Available in Size Range of 1″ to 48″, with nut, bolts and gaskets.

-

Prices for P91 alloy steel pipes ranges from US$6.5/Kg to US$8.5/Kg depending on the diameter, thickness, length and quantity of pipes.

-

-

100% Quality Guaranteed, with Competitive Prices – PED Certified, ISO Certified, Major TPI and Approvals, OHSAS Certified.

-

P91 Alloy Steel Pipe Factory, P91 Alloy Steel Pipe Suppliers in Tunisia, P91 Chrome Moly Pipe, P91 Alloy Steel Pipe Mill, P91 Alloy Steel Pipe Manufacturers, Large Diameter P91 Alloy Steel Pipe, P91 Boiler Tubes, P91 Heat Exchanger Pipes, P91 High Wall Thickness Pipes, P91 Heavy Wall Thickness Pipes, P91 Alloy Steel Pipes for Refineries, P91 Alloy Pipes for Oil & Gas Applications, P91 Steel Pipe, Super Heater A335 Gr. P91 Pipes, UNS K91560 Pipes, Grade P91 Pipes, 9Cr 1Mo Alloy Steel Pipes for Power Plants

-

We are a specialized manufacturer, stockist and supplier of A335 P91 alloy steel pipes in Tunisia. P91 alloy steel pipes contain min. 8.0% chromium and 0.85% molybdenum, and offer minimum tensile strength of 585 MPa and yield strength of 415 MPa. In comparison to alloy T22 or P22 grade pipes, grade 91 pipes exhibits high strength up to temperatures in the range of 600°C. Also the oxidation temperature limits are higher. This allows the power plant designers to engineer components, superheater coils, headers and steam piping, with less thickness. This contributes to a higher thermal fatigue life of almost ten times. This allows them to increase the operating temperature to a higher level, increasing the efficiency of the power plant.

-

A335 P91 alloy steel pipes are mainly used in power generation industry for manufacturing boilers, pipeline and heat exchangers, and are generally suitable for bending, flanging, and similar forming operations, and for fusion welding.

-

With a collective experience of over 30 years, we have emerged as one of the largest just in time exporter of P91 alloy steel pipes to Tunisia. ASTM A335 P91 alloy steel pipes are used in conjunction with ASTM A234 WP91 buttweld fittings, A234 WP91 elbow, A234 WP91 Tee, A234 WP91 reducer, A234 WP91 180 Degree U bends, and A182 F91 forged fittings and flanges. All these materials have similar chemical (Chrome, Moly, Nickel) and mechanical properties and can be easily welded and installed on site.

-

We are devoted to provide the best solutions for our customers in Tunis, Sfax, Sousse, Ettadhamen, Kairouan, Gabès, Bizerte, Aryanah, Gafsa, El Mourouj, the biggest industrial and commercial cities of Tunisia. We have manufacturing set up, sales and export offices in both India and China to meet the immediate and long term alloy steel pipe requirements across Tunisia. We aim at offering high quality but competitive price chrome moly P91 pipes for our global customers.

Professional Manufacturer of Alloy Steel SA335 P91 Pipes and Tubes, P91 U-Tubes, ASTM A335 Gr. P91 Steel Pipes and Tubes

- Welded Alloy Steel Pipe, Size Range: 1/8″ to 48″

- Seamless Alloy Steel Pipes, Size Range: 1/8″ to 48″

- Thickness – SCH 20, 30, 40, STD, XH, 80, 100, 120, 140, 160, XXH, WT is 2.11mm – 40mm

- Additional Services: Fusion Bond Epoxy, Galvanizing, 3LPE, Tar Epoxy

Are You Looking for a P91 Alloy Steel Pipes Supplier in Tunisia?

We are one of the largest P91 alloy steel pipe factory, supplier and exporter in Tunisia. We welcome you to contact us and send us your requirements. Metline specialises in export of alloy steel P91 pipes to Tunisia. We can offer CIF, Ex-Works, DDP delivery terms.

| Product | P91 Alloy Steel Seamless Pipes |

| Specification | ASTM A335, ASME SA335 |

| Grade | P91 |

| Size | 2″ to 48″ |

| Thickness | 2.11 mm to 160 mm |

| Type | Seamless, Hot Rolled, Cold Drawn |

| Test Certificates | EN 10204 3.1 |

| Length | 6 MTR, 12 MTR, Custom |

Equivalent Grades & Applications for P91 Alloy Steel Pipes

| Material Group | Common Name | Type | UNS | Forging Spec. | Casting Spec. Equivalent | DIN | DIN W. No | Application |

| Low Alloy Steel | Moly Steel | C-1/2Mo | K12822 | A182-F1 cl2 | A217-WC1 | 15M03 | 1.5415 | Up to 470ºC* (875ºF) |

| Alloy Steel Chrome Moly | 1.1/4Cr-1/2Mo | K11572 | A182-F11 cl2 | A217-WC6 | 13CRM044 | 1.7335 | Up to 593ºC (1100ºF) | |

| 2.1/4Cr-1Mo | K21590 | A182-F22 cl3 | A217-WC9 | 10CRM09-10 | 1.738 | Up to 593ºC (1100ºF), High Pressure Steam | ||

| 5Cr-1/2Mo | K41545 | A182-F5/F5a | A217-C5 | 12CRMO195 | 1.7362 | High Temperature Refinery Service | ||

| 9Cr-1Mo | K90941 | A182-F9 | A217-C12 | X 12 CrMo 9 1 | 1.7386 | High Temp Erosive Refinery Service | ||

| 9Cr-1Mo-V | A182-F91 | A217-C12A | X 10 CrMoVNb 9 1 | 1.4903 | High Pressure Steam |

- The equipment and pipelines in the power generation industry are manufactured from chrome-molybdenum P91 alloy steel pipes, also known as A335 P91 Gr. pipes. We are a specialist supplier of P91 steel pipes to various power generation units in Middle East, Africa and Eastern Europe.

- P91 alloy steel pipes contain high amount of Chromium. Grade 91 contains 9 % Chromium and 1 % Molybdenum compared to 2.5 % Chromium in the next best P22 grade. Chromium improves high temperature strength and increases oxidation resistance. Molybdenum increases the creep resistance. Also present are smaller quantities of Nickel and Manganese which increase the hardenability of the steel. The more Cr and Mo added, the stronger the steel will be. Accordingly, a piping designer can decide whether they want to use a stronger material like P91 (9% Cr, 1% Mo and additional alloying elements)1 with a thinner wall or a thicker wall pipe of lower strength like P22 (2.3% Cr & 1% Mo) or even P11 (1.25% Cr & .55% Mo).

- In general, the most commonly used chome moly grades in refineries are P5 & P9. The most commonly used alloy steel pipe grades in the power generation industry and petro-chemical plants are P11, P22 & P91.

- Heat treatment of P91 alloy steel pipes is very important, and if heat treatment is not properly done there are high chances of failure in materials. If P91 steel pipes are not adequately heat treated then the steel has properties that are much lower than its predecessor P22.

ASTM A335 is a standard specification for seamless ferritic alloy-steel pipe for high-temperature service. The specification generally covers “chrome-moly” seamless pipes with remarkable resistance to corrosion and good tensile strength at high-temperature service. The testing requirements for these pipes include the following:

- Transverse/longitudinal: tension and flattening, hardness, bend tests- for material which has been heat-treated in batch furnaces, these tests shall be made on the 5% of the pipes from each heat lot number. For smaller lots, one pipe at a minimum has to be tested

- ASTM A335 Gr. P91 shall have a hardness of 250 HB / 265 HV (25 HRC)

- Hydro testing: shall be applied to every length of pipe

- The non-destructive electric test is optional

Equivalents of Alloy Steel Pipes Under DIN, ASTM and EN

| DIN | EN | ASTM |

| 1.5415 | 16Mo3 | A335 Grade P1 |

| 1.7335 | 13CrMo4-5 | A335 Grade P11, P12 |

| 1.738 | 10CrMo9-10 | A335 Grade P22 |

| 1.7362 | X11CrMo5 | A335 Grade P5 |

| A335 Grade P9 | ||

| 1.4903 | X10CrMoVNb9-1 | A335 Grade P91 |

Chemical Composition of Alloy Steel Chrome Moly Pipes – ASTM A335 P5, P9, P11, P22, and P91

| Grade | C | Mn | P | S | Si | Cr | Mo |

| P5 | 0.15max | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 4.00-6.00 | 0.45-0.65 |

| P9 | 0.15 max | 0.30-0.60 | 0.025 | 0.025 | 0.25-1.00 | 8.00-10.00 | 0.90-1.10 |

| P11 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

| P22 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 1.90-2.60 | 0.87-1.13 |

| P91 | 0.08-0.12 | 0.30-0.60 | 0.02 | 0.01 | 0.20-0.50 | 8.00-9.50 | 0.85-1.05 |

| V 0.18-0.25 | N 0.03-0.07 | Ni 0.40 max | Al 0.02 max | Cb 0.06-0.10 | Ti 0.01 max | Zr 0.01 max |

Mechanical Properties of Alloy Steel Chrome Moly Pipes – ASTM A335 P5, P9, P11, P22, and P91

| Grade P11, P22, P5, P9 | Grade P91 | |

| Tensile strength, min, psi, (MPa) | 60,000 (415) | 85,000 (585) |

| Yield strength, min, (MPa) | 30.000 (205) | 60,000 (415) |