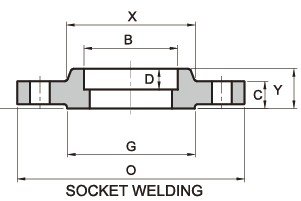

ASME/ANSI B16.5 600 Class Socket Welding Flange/Standards, Dimensions & Weight

The SW forged flange shares similarities with slip-on and socket welding flanges, but has a counter-bored bore that can accommodate pipes. The remaining diameter of the bore matches the inside diameter of the pipe. A fillet weld is used to attach the Socket Welding Flange to the pipe’s hub, while an additional internal weld may be necessary for high-stress applications. Socket Flanges are widely used in high-pressure systems like hydraulic and steam lines.

| Product | Socket Welding Flange |

|---|---|

| Pressure Rating | 600 lb, 600 Class |

| Dimensional Specification | ASME/ANSI B16.5 |

| Size | 1/2″ to 24″ |

| Surface Treatment | Anti-rust Oil, Paint, Zinc, Hot Dipped Galvanized |

| Grades | 304, 304L, 316L, 321, 347, 904L, Duplex, Carbon Steel, Nickel Alloys |

| Test Certificates | As per EN 10204 3.1 |

| Inspection | Videos, Pictures, Inspection Report with Goods |

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub | Bore | Depth of Socket |

Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

Approx. Weight | ||

| inch | dn | O | C | X | G | Y | B | D | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 22.9 | 9.7 | 66.5 | 15.7 | 4 | 1/2″ | 1 | 2.2 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 28.2 | 11.2 | 82.6 | 19.1 | 4 | 5/8″ | 1.6 | 3.5 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 35.1 | 12.7 | 88.9 | 19.1 | 4 | 5/8″ | 1.8 | 4 |

| 1-1/4″ | 32 | 133. 5 | 20.6 | 63.5 | 63.5 | 28.4 | 43.7 | 14.2 | 98.6 | 19.1 | 4 | 5/8″ | 2.6 | 5.7 |

| 1-1/2″ | 40 | 155. 5 | 22.4 | 69.9 | 73.2 | 31.8 | 50 | 15.7 | 114.3 | 22.4 | 4 | 3/4″ | 3.3 | 7.7 |

| 2″ | 50 | 165. 0 | 25.4 | 84.1 | 91.9 | 36.6 | 62.5 | 17.5 | 127 | 19.1 | 8 | 5/8″ | 3.9 | 8.6 |

| 2-1/2″ | 65 | 190. 5 | 28.4 | 100.1 | 104.6 | 41.1 | 75.4 | 19.1 | 149.4 | 22.4 | 8 | 3/4″ | 6 | 13.2 |

| 3″ | 80 | 209. 5 | 31.8 | 117.3 | 127 | 46 | 91.4 | 20.6 | 168.1 | 22.4 | 8 | 3/4″ | 7.4 | 16.3 |

| 3-1/2″ | 90 | 228. 5 | 35.1 | 133.4 | 139.7 | 49.3 | 104.1 | 184.2 | 25.4 | 8 | 7/8″ | 9.5 | 20.9 | |

| 4″ | 100 | 273. 0 | 38.1 | 152.4 | 157.2 | 53.8 | 116.8 | 215.9 | 25.4 | 8 | 7/8″ | |||

| 5″ | 125 | 330. 0 | 44.5 | 189 | 185.7 | 60.5 | 144.5 | 266.7 | 28.4 | 8 | 1″ | |||

| 6″ | 150 | 355. 5 | 47.8 | 222.3 | 215.9 | 66.5 | 171.5 | 292.1 | 28.4 | 12 | 1″ | |||

| 8″ | 200 | 419. 0 | 55.6 | 273.1 | 269.7 | 76.2 | 222.3 | 349.3 | 31.8 | 12 | 1 1/8″ | |||

| 10″ | 250 | 508. 0 | 63.5 | 342.9 | 323.9 | 85.9 | 277.4 | 431.8 | 35.1 | 16 | 1 1/4″ | |||

| 12″ | 300 | 559. 0 | 66.5 | 400.1 | 381 | 91.9 | 328.2 | 489 | 35.1 | 20 | 1 1/4″ | |||

| 14″ | 350 | 603. 5 | 69.9 | 431.8 | 412.8 | 93.7 | 360.2 | 527.1 | 38.1 | 20 | 1 3/8″ | |||

| 16″ | 400 | 686. 0 | 76.2 | 495.3 | 469.9 | 106. 4 | 411.2 | 603.3 | 41.1 | 20 | 1 1/2″ | |||

| 18″ | 450 | 743. 0 | 82.6 | 546.1 | 533.4 | 117. 3 | 462.3 | 654.1 | 44.5 | 20 | 1 5/8″ | |||

| 20″ | 500 | 813. 0 | 88.9 | 609.6 | 584.2 | 127. 0 | 514.4 | 723.9 | 44.5 | 24 | 1 5/8″ | |||

| 24″ | 600 | 940. 0 | 101.6 | 717.6 | 692.2 | 139. 7 | 616 | 838.2 | 50.8 | 24 | 1 7/8″ | |||

Note:

1) Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.