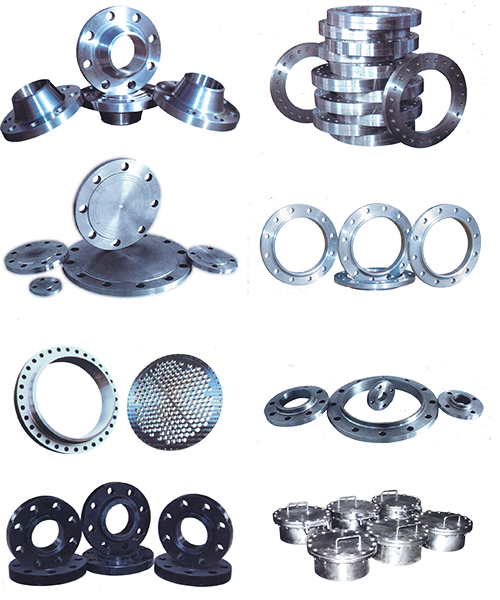

Steel Flanges are Among our Best-selling Products in Trinidad and Tobago because we Offer Competitive Price and Best Quality

With precision machining facilities and low prices, we are a professional flange manufacturer and supplier in Trinidad and Tobago. For flanges, we use a heat treatment process and examine their chemical and mechanical properties. We have CNC machines as well as conventional lathe machines for machining and processing various types of flanges.

- Flanges are generally made from forged carbon, alloy and stainless steel bar stock. The raw materials used for manufacturing steel flanges include raw round bar of diameter size 20~400mm OD. Steel flanges manufactured as per ASTM/ASME or DIN standards are supplied to Trinidad and Tobago in size range of 1/2″ to 60″.

- Metline is a large producer of various type of flanges such as Weld-neck, Slip-on, Socket-weld, Lap-joint, Blind and Threaded Types. We produce and forge flanges to specifications of ASME B16.5, ASME B16.47, ASME B16.48, BS EN 1092, BS 4504, API-605, API-590, MSSSP44, DIN 2632 to 2638, DIN 2576, 2642, 2527, 2566. At Metline, flanges cover a full range of pressure ratings of these specifications (150 – 2500 psi for ASME & PN6-PN400 for DIN/EN flanges). We also specialize in producing non-standard flanges upto a diameter of 4500 mm.

- We produce custom size flanges as per customer drawings.

Why Choose Metline, as Your Supplier for Steel Flanges in Trinidad and Tobago?

- More Than 3 Decades of Experience in Stock & Supply of Pipe Flanges

- Best Prices For Flanges Manufactured by Metline and Exported Worldwide

- Exporting Steel Flanges is Our Specialty

- We Can Handle the Logistics for You – We can offer Exworks, FOB, CFR, CIF Delivery to Any Port

- Documents We Provide Include – Certificate of Origin, Invoice & PL Attested by Chamber of Commerce, Test Certificates as per EN 10204 3.1, Other Testing Reports, as may be Required by Our Customers.

- Complete Traceability for Flanges – All Our Products will have Complete Marking on Flanges and/or Packaging, and the Details can be co-related to the Test Certificates.

Reviews

There are no reviews yet.